Andrew Sargent, general manager of Advanced Air, examines the chilled beam market and the impact that a new generation of energy efficient ec fan coils could have on the demand for these systems.

Chilled Beams are really quite a recent addition to the terminal air conditioning market introduced by European manufacturers to the UK market in the late 1990s. As with all European systems, they do become anglicised to have greater appeal to the special needs of the UK market. One example was the multi-service chilled beam.

The idea appealed to architects particularly on refurbishment projects of old concrete buildings where there was limited space.

The value to the manufacturer of fully-integrated multi-service chilled beams with all of the services installed could be as much as eight times compared to a standard fan coil unit. Hence the published marketing figures were inflated by the inclusion of all the other services such as lighting, controls, sensors, etc.

When the new building regulations were issued in 2002, designers focused much more on carbon emissions and here the chilled beam was way out in front of fan coil systems. The difference in the predicted carbon emissions would vary from project to project but claims of over 30 per cent savings were often made for chilled beams.

A recent article comparing carbon emissions of ac constant speed fan coils and chilled beams, (using measured data from the same manufacturer), showed a saving in carbon emissions of 23.3 per cent when using the chilled beam system. With increasing focus on carbon emissions and new tighter building regulations issued in 2006, it is no wonder that the sales of chilled beams increased dramatically with year-on-year growth of up to 40 per cent.

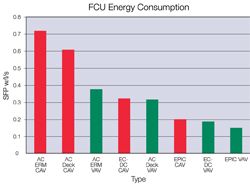

Figure 1

So the driving force in the dramatic increase in the market value of chilled beams was the carbon emission comparison of the two systems. These systems are worldwide and probably the most popular globally. In the UK they have been installed for more than 50 years and most of the time have been the system of choice for consulting engineers. For that to continue, manufacturers had urgently to address the energy efficiency issue and introduce a new generation of fan coils that could match the carbon credentials of chilled beams.

With the introduction of highly efficient ec motors the carbon emissions of fan coils was reduced significantly.

A measure of the efficiency of a fan coil is directly related to the specific fan power (SFP) in watts/l/sec. The external rotor motors, popular in the 1990s, had an SFP typically of 0.8. In other words, it would consume 0.8 Watts for every litre/second of air movement.

Figure 2: Epic Fan Coil Unit

A European-manufactured ec motor in comparison would have an SFP of around 0.3 which is a significant saving in energy.

Figure 1 gives SFP for a wide range of fan coil systems and, as can be seen, very low figures can now be achieved. A further improvement to the SFP can be made by varying the total air volume of the fan which can be easily achieved with the ec motor. Because of the cube relationship between Watts consumed and air flow there is a significant saving in energy with only a small reduction in speed as indicated in the table below right.

These are calculated values to show the effect of the cubic relationship, actual values have been measured and are very close to these figures. These measures drastically reduce the carbon emissions of the fan coils and are now within 5 per cent of the chilled beam energy figures.

A further increase in fan coil energy efficiency can be made by improving the fan deck design. Traditionally, a vertically-mounted centrifugal fan has been used and, to keep the fan coil height to a reasonable dimension so that it could easily fit into the ceiling void, multiple small (low height) fans were used. The European ec fan deck has up to five motors each with their individual fan.

These fan decks are normally bought in by the fan coil manufacturer either from the motor supplier or another manufacturer.

At Advanced Air we design and manufacture our own fan decks which means we can adapt the fan configuration quite easily. We also have a strong working relationship with our American-based ec motor manufacturer with full access to its R&D facilities. By combining the expertise of both companies we were able to develop a fan deck with only one fan horizontally mounted (

as per Figure 2). This innovation gave us a much lower SFP and a more efficient fan coil which neutralises the carbon emission argument between the two systems.

The future

Consultants are already responding positively to this new generation of highly efficient fan coils. Deep down consultants seem to prefer fan coils to chilled beams because of their flexibility and lower capital cost which will become even more important where all designers have to prove their designs represent good value for money.

The carbon emissions arguments for chilled beams were so powerful at the time that, although there were premiums to be paid for using this system, it still grew dramatically. That situation does not exist now and I think we will see chilled beams becoming more of a niche market, particularly with the multi-service chilled beam.