Geoff Sheard, group vice-president, fan technology, is Fläkt Woods’ most senior engineer. Here, he looks at the changes to Part L and how the new regulations mean that information must be provided so that occupiers may maintain and operate a building efficiently.

THE new Part L Building Regulations differ from the version they replace in that they are systemic in nature. For the first time, the guidance calls for 'energy efficient systems' in buildings that are air-conditioned or mechanically ventilated. New regulations now address the performance of air conditioning and mechanical ventilation systems that serve floor areas of more than 200m2, and the insulation of cold air distribution ducting and chilled water and refrigerant services.

This means that for air-tightness of buildings of any size, satisfactory results of air pressure tests would be acceptable, or alternatively, for buildings with floor areas of less than 1000m2, reports of satisfactory design and construction could be acceptable. A new requirement calls for information to be provided to enable building occupiers to operate and maintain the building and its services effectively.

As a result, developers with multi-level commercial or residential buildings are increasing looking at installing constant pressure systems controlled by either Passive Infra Red (PIR) occupancy detectors or switched live automatic systems either in individual rooms or apartments, or as a common ventilation system serving multiple levels. This ensures ventilation is activated only during periods of occupancy which minimises running costs.

Fig 2

Our changing ways

Lifestyles and more flexible working hours mean buildings are open longer and with varying occupancy levels. Rising energy costs associated with running plant continuously have created a demand for either user control or system-managed control.

To enable the designer of the system to optimise the power consumption and system performance, and comply with the requirements of the new Building Regulations, Fläkt Woods has developed the iFan range to offer a multi sensor/switch control package for use with fans from the Express Range. The control system is designed to operate either with a constant pressure system or in conjunction with room sensors.

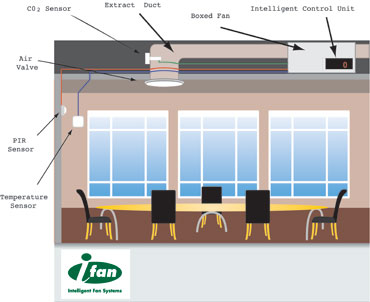

At its most basic level a ventilation system can contribute to improving the energy efficiency of buildings by having some built-in intelligence such that it operates only when needed. The fans used in ventilation systems are not inherently intelligent, they are devices that must be controlled in an intelligent way. The intelligence, therefore, must be built into a control unit, (Fig1). The intelligent control unit takes input, and then through the use of a programmable device takes action to control the devices attached to it in a way that takes into account the input conditions.

For larger buildings, a combination of continuous heat recovery or positive pressure, plus individual multipoint or sensor- operated unit extractor fans in kitchens and bathrooms, will cover all eventualities.

Better air quality

Natural ventilation is not an efficient method of aeration, air leakage through the building envelope accounts for between 25% and 40% of the energy used for heating and cooling. Part L regulations will ensure tighter construction methods are enforced to reduce air leakage and accidental ventilation

Supply ventilation creates positive indoor pressure. This proactive approach to ventilation results in improved indoor air quality. Fresh outdoor air is provided continuously regardless of weather conditions. Indoor air quality is improved where fresh outdoor air, low in pollutants, mixes with indoor air, which has become stale from human activity.

Fresh air is provided to the working spaces through properly sized and located ducts and vents without causing uncomfortable drafts. Filters and dehumidifiers can be added to the system near the intake further to remove pollutants and provide humidity control needed in hot, humid climates. Thus, they can be used safely with all types of heating and cooling equipment.

Less energy is consumed to operate ventilation systems than to heat and cool excessive amounts of outdoor air that infiltrates leaky buildings. As dry air costs less to heat than moist air, this form of ventilation can reduce heating bills, despite bringing in a small amount of outside air which may be below the internal air temperature at certain times of the year.

How it works

The system works on sensors which can either be manually adjusted or electronically controlled. Sensors that can be manually adjusted by the room occupant have a disadvantage in that the fan can be left running at high speed and thus waste energy through over ventilating the space. Human nature is to increase fan speed when required but to forget to reduce the fan speed later when this may be possible.

Sensor inputs provide a more sophisticated method of controlling the fan. The set points are adjusted at the time of commissioning the system and cannot be altered by the occupant. This minimises energy use and allows the set point to be obtained quickly and accurately through a Proportional Integral (PI) loop. Typical sensors used to provide input to an intelligent control unit include:

· Air quality. The sensor may for example detect tobacco smoke in a bar or CO2 in a meeting room. Fan speed is increased as the level of pollutant increases.

· Temperature. The temperature in the room is measured and controlled to the set point. An increase in temperature may be due to increased occupancy or activity in the room or solar gain from outside.

· Humidity. Again the method of operation is similar to temperature but measures humidity in say a bathroom or kitchen.

It is of course possible to use a combination of sensors. A meeting room for instance may have both CO2 and temperature sensors. The fan speed is controlled according to the temperature and CO2 levels in the room. The higher signal always controls the fan speed, hence fan speed is increased on a sunny day when the occupancy is low and the temperature increases; or on a cloudy cool day when the room occupancy and CO2 level is high.

A further level of control may be introduced by including an occupancy sensor. This then means that the room is only fully ventilated when occupied and trickle ventilation used when empty.

The example (fig2) is for a room-mounted PIR, temperature sensor and duct mounted CO2 sensor. A typical application for this type of arrangement would be an enclosed office, conference area or lecture theatre.

Initially, the intelligent ventilation system is passive, switched off, as the room is not occupied. When the PIR detects movement, this indicates the room is occupied and the intelligent control unit uses this input as the trigger to activate the fan and start responding to the other sensors connected to it. When running at minimum speed the fan extracts air from the room at a rate sufficient to provide trickle ventilation to the room.

As time passes the number of people in the room may increase, and if this is an office, as the day progresses, the level of solar gain into the room may increase. Both will have the effect of increasing room temperature. When temperature rises above a pre-set limit, the temperature sensor in the room will detect the rise in temperature, with the sensor sending a signal to the intelligent control unit to increase fan speed.

Fig 3

As fan speed is increased, so the rate at which the warm air is extracted from the room is increased (fig3).

Over time the increasing number of people in the room will cause the CO2 level to increase. To maintain CO2 at no greater then a pre-set level, a duct-mounted sensor monitors CO2 level in the air being extracted from the room. When the CO2 level increases above a pre-set level the sensor sends a signal to the intelligent control unit which in turn increases fan speed to lift the rate at which stale air is being extracted from the room (fig4).

Fig 4

As time passes, the room occupancy and solar gain reduce. The reduction in heat input into the room at constant fan speed results in the room starting to cool. The temperature sensor detects this fall in temperature and sends a signal to the intelligent control unit that reduces the fan speed accordingly. When all the occupants have left, the PIR no longer detects movement.

An alternative method of controlling the fan is to use a pressure sensor. The sensor measures pressure in the ductwork adjacent to the fan. The fan speed is then varied to maintain a constant pressure in the duct.

A typical installation working on pressure control will include a number of duct air valves in the occupied space. These valves are actuated by sensing occupancy, either by a PIR device or by a switched live input connected in series with a lighting circuit. With the room unoccupied the valves are in the closed position but still allow a minimal passage of air through them to act as trickle ventilation. When the room is occupied the valves open and pressure inside the duct decreases. In order to maintain a constant pressure the fan speed increases and ventilation to the room is also increased. When the occupants leave the valves close and pressure in the duct increases.

The fan speed then decreases to maintain the pressure set point, returning the ventilation rate to trickle. A run on timer can be incorporated to allow ventilation for a pre-set time after the occupants leave.